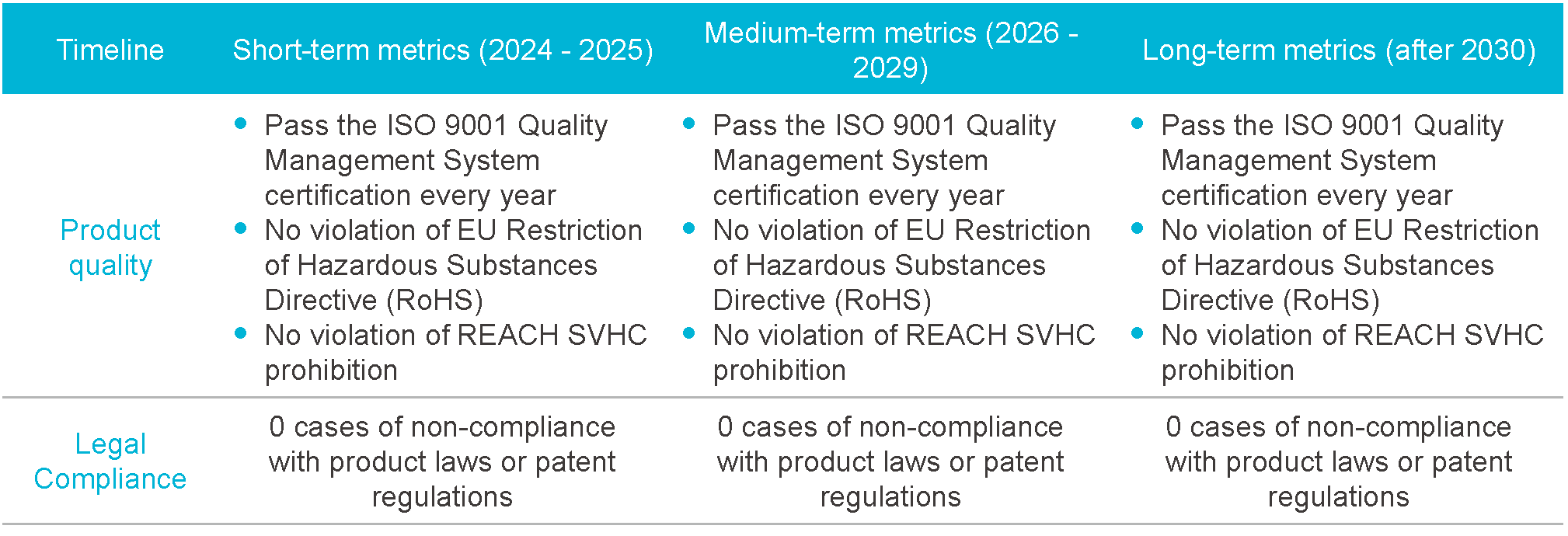

Kaori has developed its own quality management system in accordance with ISO 9001:2015 Quality

Management System and implemented a series of management procedures and operational guidelines to

guide quality management practices throughout the Company. Furthermore, Kaori has open communication

channels in place to gather customers' opinions, quality feedback, audit findings, etc., for ongoing

improvements. The Company will continue listening to customers' voices and adopting total quality

management to satisfy customers' needs.

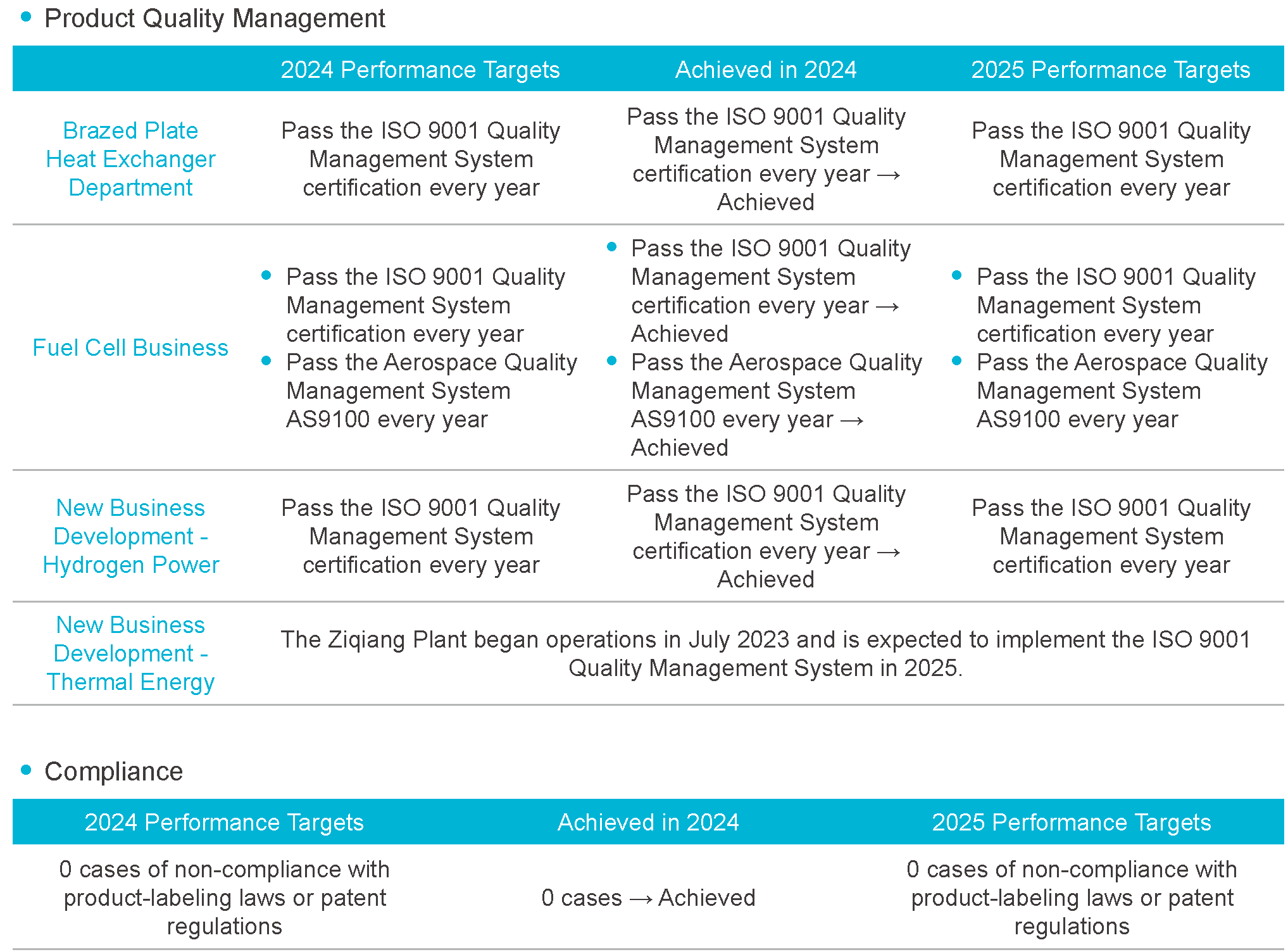

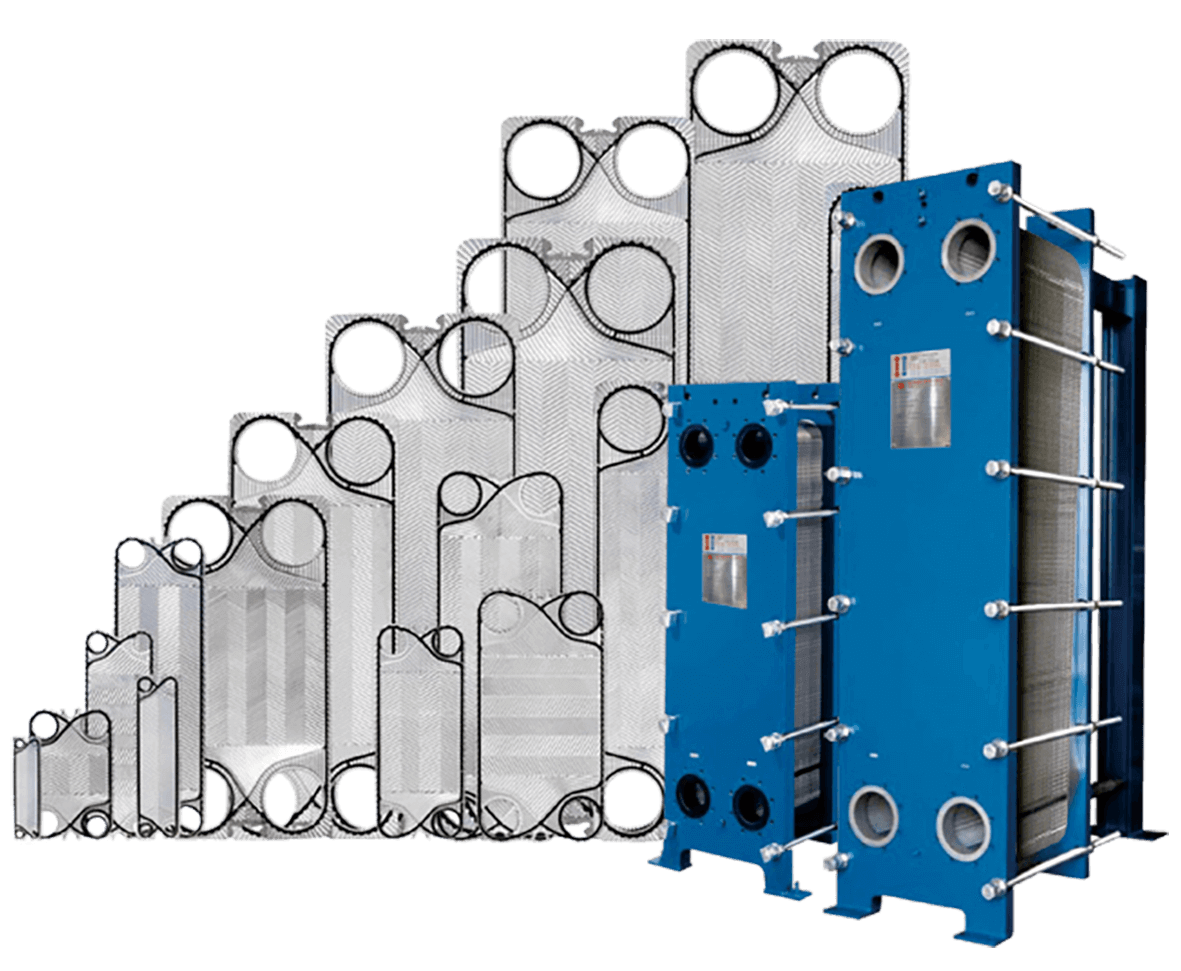

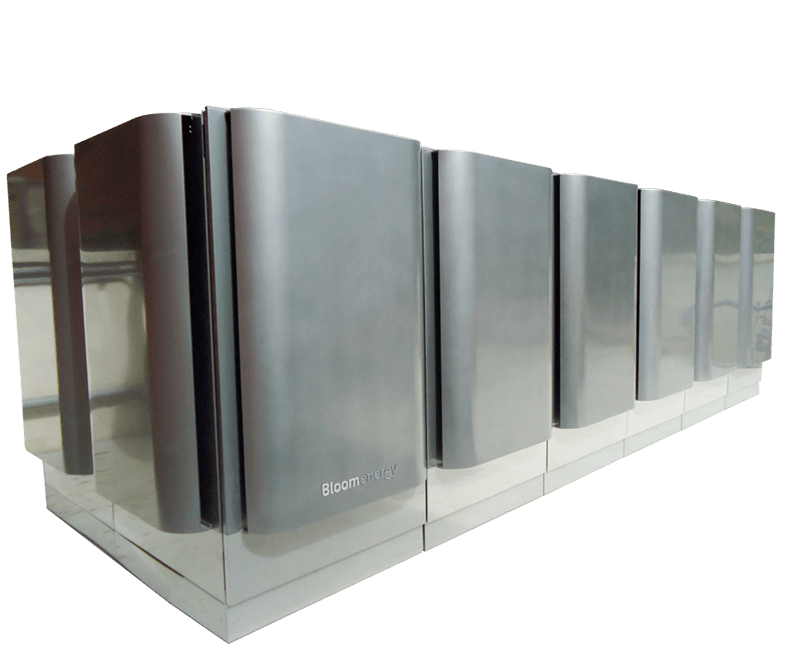

All of the Company’s business units were certified under the latest international quality management system,

ISO 9001:2015, in 2020. In addition, the Fuel Cell Division obtained certification for the latest aerospace

quality management standard, AS9100:D, in February 2022. These certifications guide the Company in its

continuous improvement efforts, enabling the delivery of the most reliable quality and services to customers.

Kaori remains committed to its customer-centric service philosophy and refrains from all actions that

compromise product quality or endanger customers' safety. By making quality a part of our corporate culture

and employees' conviction, we strive to become customers' trusted partner and work with customers and

suppliers toward sustainability.

The Company encountered zero instances of product recalls due to safety concerns or otherwise in 2023

and suffered no financial losses from lawsuits concerning product safety.

Quality Policy

Quality Assurance

To bring traceability into the products manufactured, Kaori has adopted an enterprise resource planning (ERP) system and a manufacturing execution system (MES) that digitally integrate all processes from material purchase, storage, production, and quality management to financial management. These systems record the details of every production stage and ensure that accurate data can be generated quickly to support Kaori's commitment to quality assurance.

Site Management

- Safety management

1.Zero hazard activities: safety rules, safety education, and safety inspection standards have been outlined.

2.5S management: