Dual International Carbon Management Certification

The world's first plate heat exchanger manufacturer to receive a dual certification of ISO 14064-1 for greenhouse gas inventory and ISO 14067 for carbon footprint from a third party.

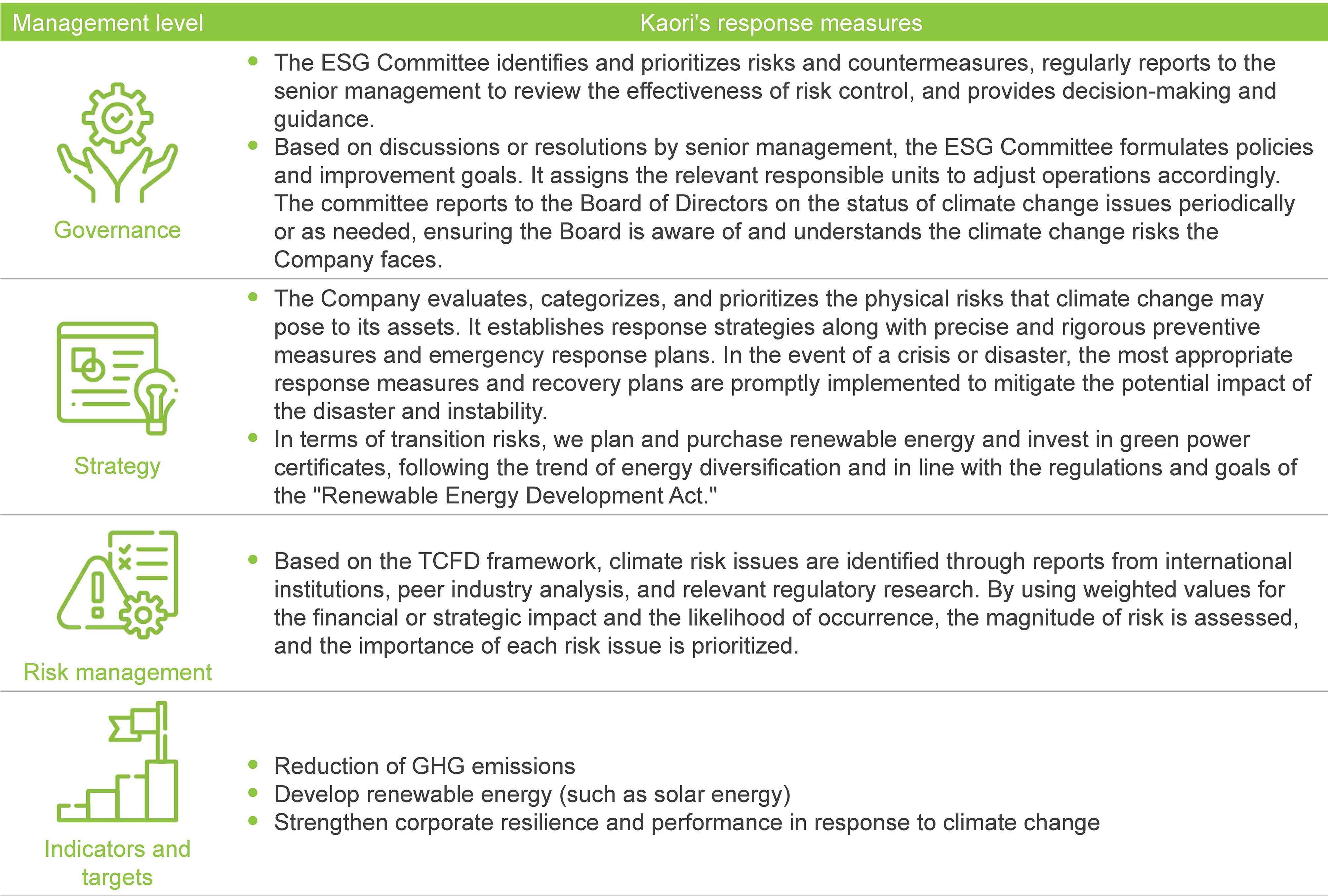

Climate change is one of the environmental issues currently of concern to the United Nations, governments, society, and the business community. Kaori, in accordance with the 2019 Task Force on Climate-related Financial Disclosures (TCFD) Recommendations established by the International Financial Stability Board, has set the following governance, strategy, risk management, and metrics and targets for the company, as outlined in the table below:

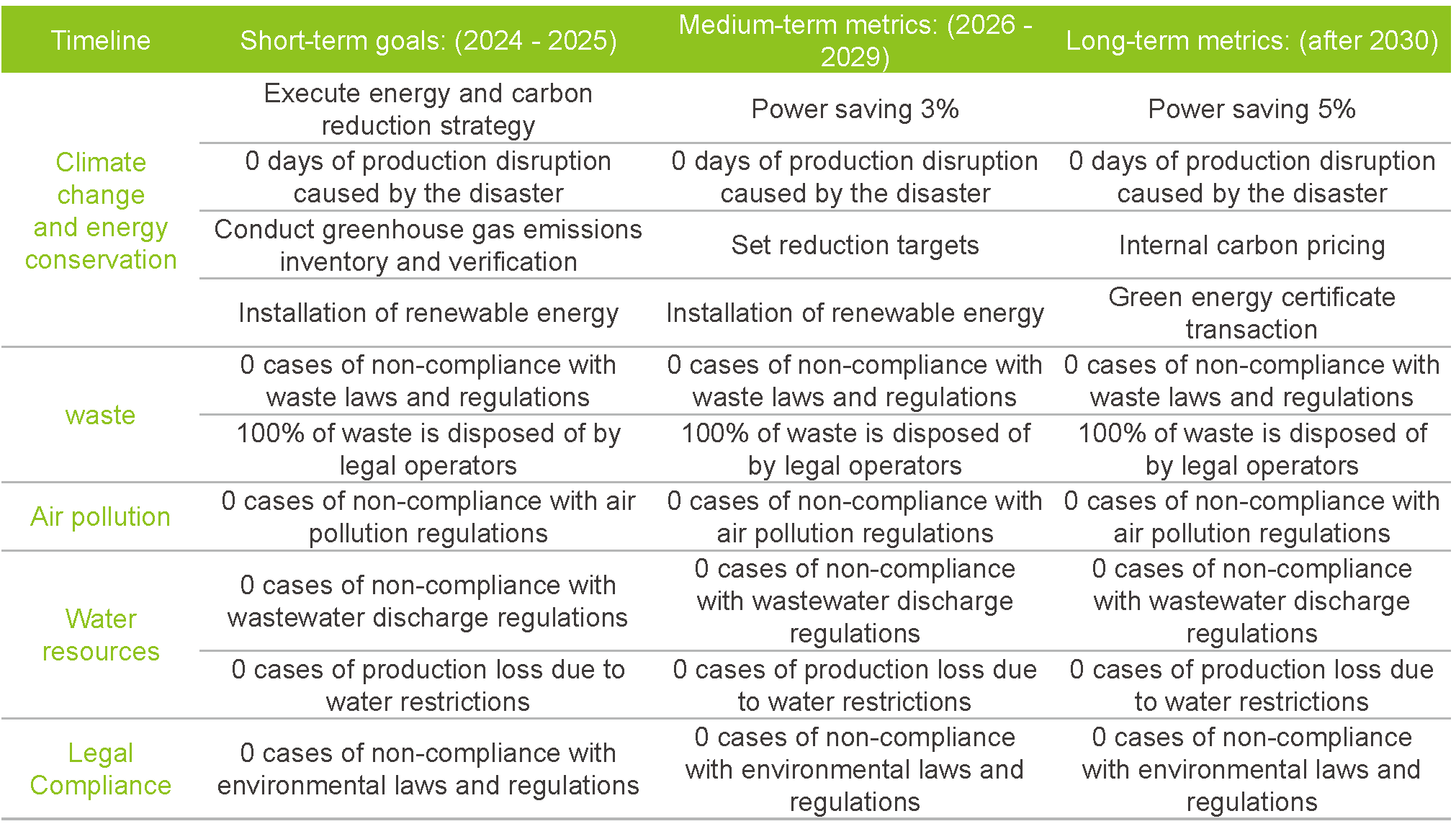

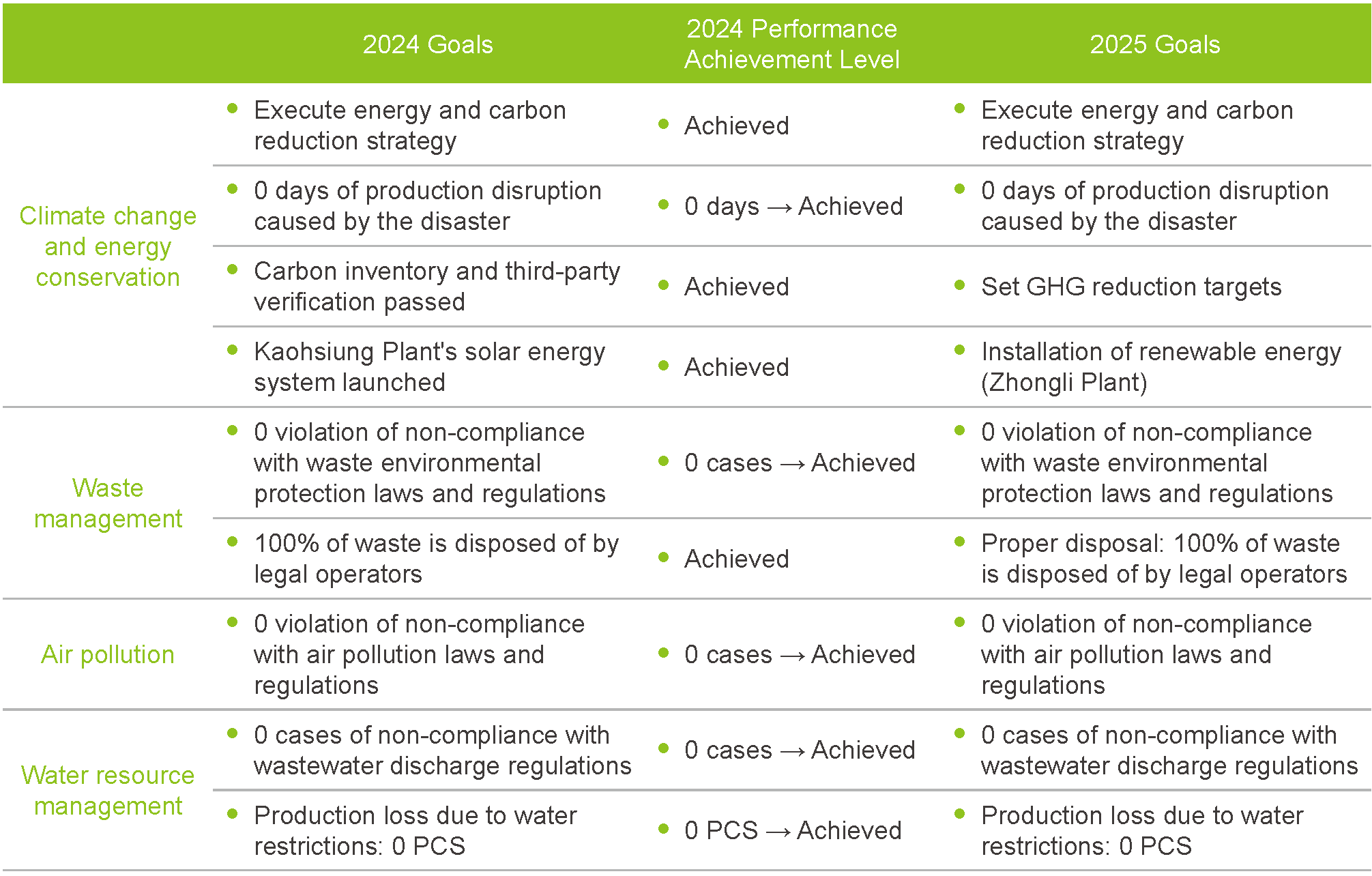

Kaori is committed to fulfilling its environmental responsibility and becoming a sustainable business with continuous improvement. In line with the short-, medium-, and long-term energy-saving and carbon reduction metrics and related implementation plans mentioned above, we have set and achieved performance goals over the past two years (as shown in the table below) to reduce potential impacts on society and the environment.

0 %

0 %

In 2024, the Company did not violate environmental protection laws and regulations resulting in penalties from regulatory authorities.

The world's first plate heat exchanger manufacturer to receive a dual certification of ISO 14064-1 for greenhouse gas inventory and ISO 14067 for carbon footprint from a third party.

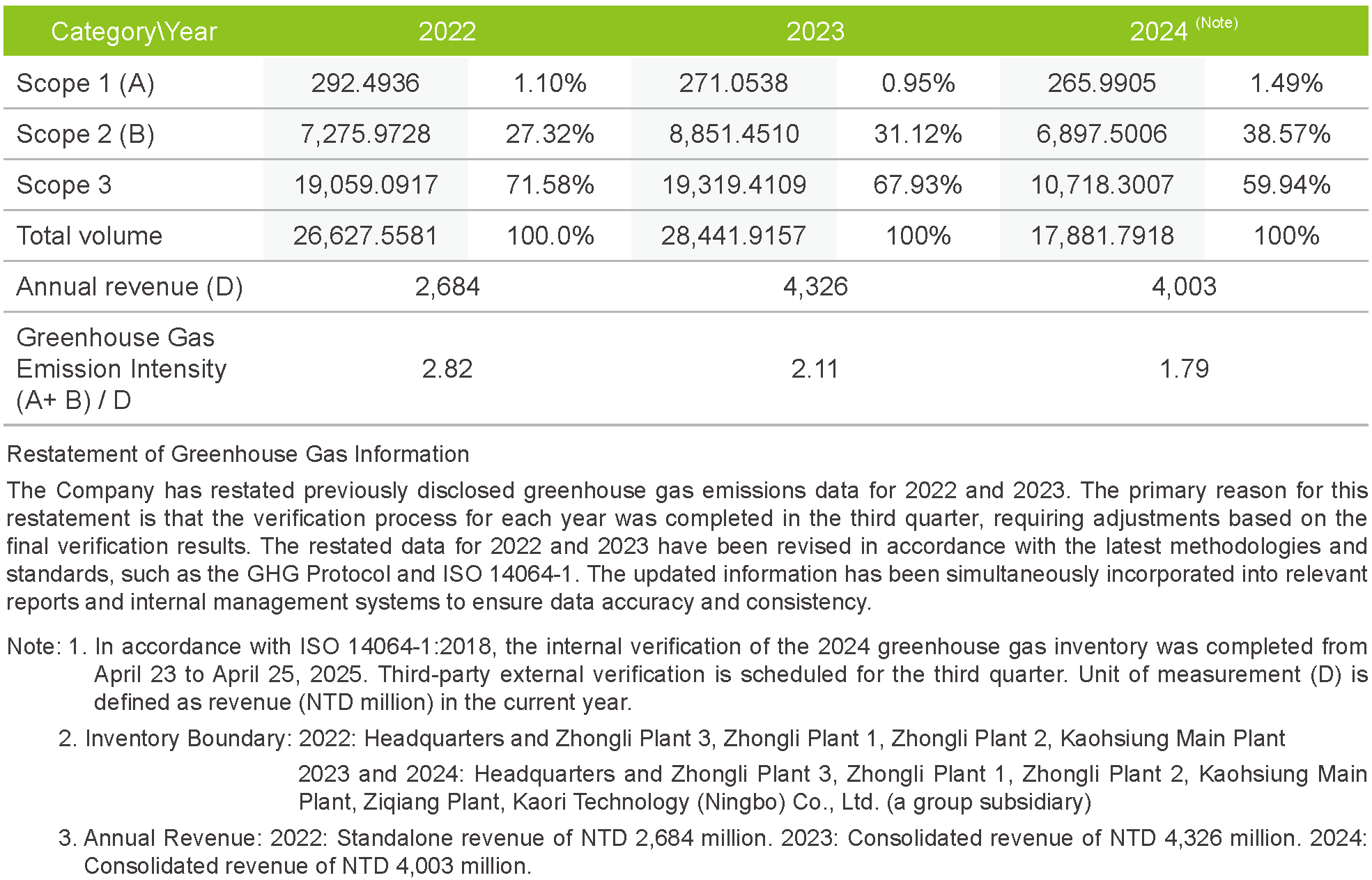

The carbon intensity was 15.14% lower compared to 2023.

In 2024, a total of three energysaving measures were implemented, resulting in electricity savings of 528,692 kWh (equivalent to 1,903,291.2 MJ), with a financial benefit of NTD 2,533,148.

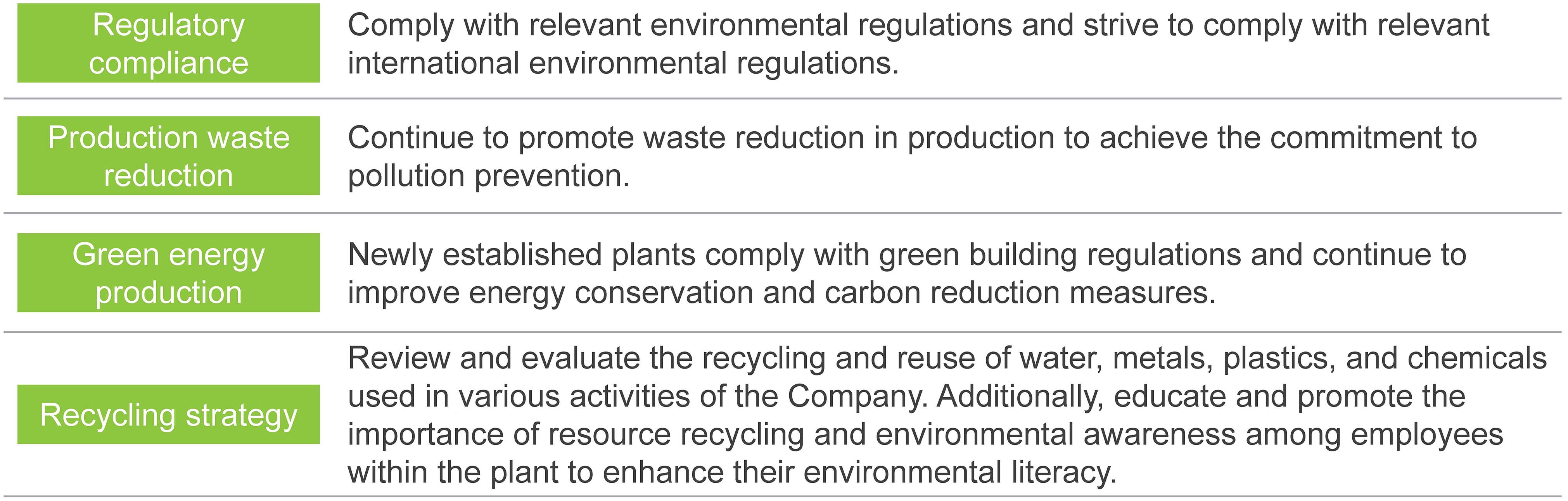

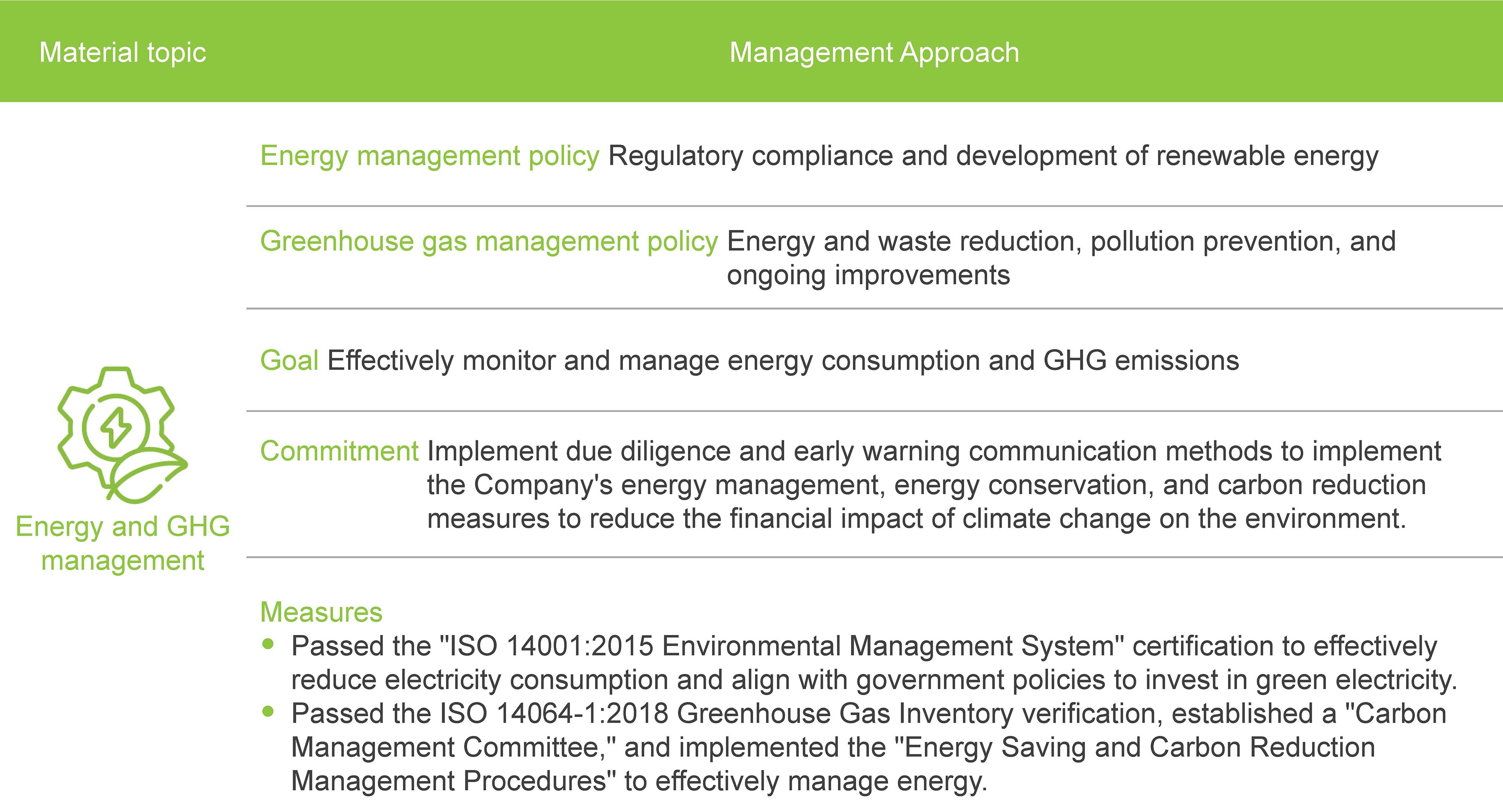

In terms of environmental policy, Kaori is committed to fulfilling its environmental protection responsibilities and becoming a sustainable enterprise through continuous improvement:

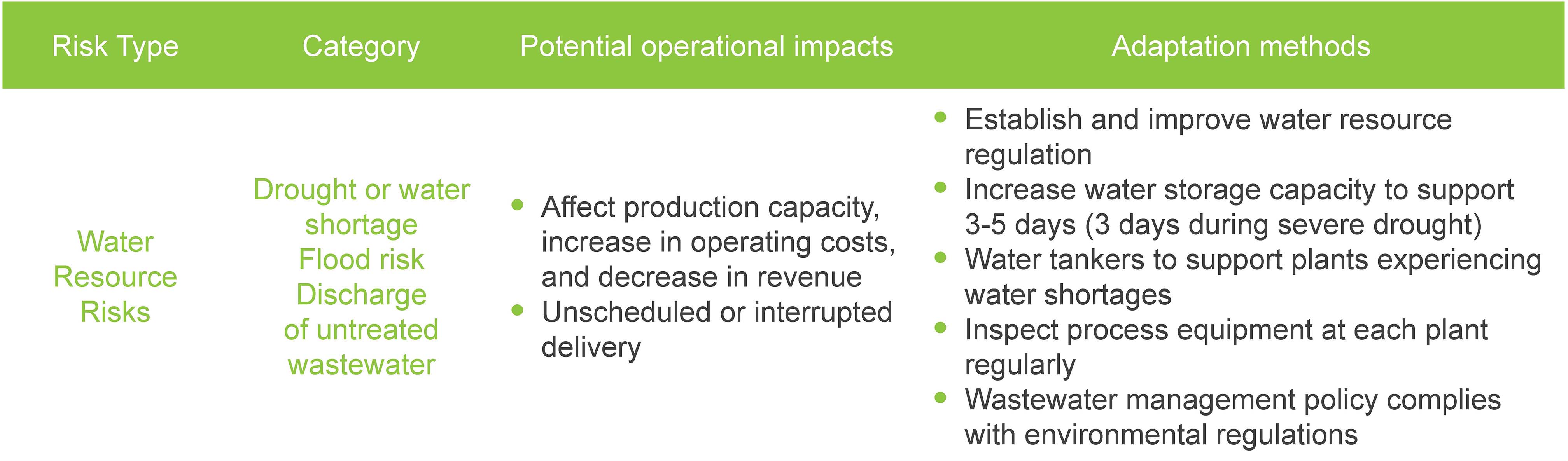

Kaori has established an appropriate environmental management system in accordance with ISO 14001:2015 (Figure 1) and set up a dedicated unit to take charge of environmental management and maintenance. Evaluate the environmental pollution considerations across the product life cycle, and continuously improve the environmental system through internal management practices to reduce negative impacts, aiming to contribute to environmental protection. In response to climate change and energy supply risks, Kaori actively identifies climate change risks such as floods, droughts, typhoons, power outages, and water shortages.

In addition, we have introduced the ISO

14064-1:2018 Greenhouse Gas Checklist

Statement (Figure 2) to regularly control

the impact and damage to operations

caused by extreme weather. We have

formulated climate risk adjustment policies

and focused on controlling oil/oil with high

carbon emissions, actively implementing

relevant measures and solutions to reduce

carbon emissions.

In 2024, the Company did not violate

environmental protection laws and

regulations resulting in penalties from

regulatory authorities.

To closely monitoring climate change, Kaori has made climate change one of the major issues for sustainable development and taken the initiative to disclose relevant information according to the requirements of the report preparation guidelines mentioned above. Through inter-departmental communication, discussions are made on the possible scenarios, the likely impacts, and the timing of impacts on Kaori. Each of the scenarios identified is further evaluated to facilitate proper control and response to the associated risks and opportunities. By adopting a more pro-active governance approach toward climate change, Kaori takes pragmatic steps to fulfill its sustainability vision.:

Kaori contributes its part to environmental protection and social values by enforcing energy management throughout its operations and by investing into the research and development of new materials and production procedures. A Carbon Management Committee has also been assembled to oversee GHG reduction, energy/resource conservation, water conservation, waste recycling, and mitigation of environmental impact. At the same time, Kaori continues to invest into environmental protection facilities and incorporate green management and energy conservation practices into business activities for sustainable growth.

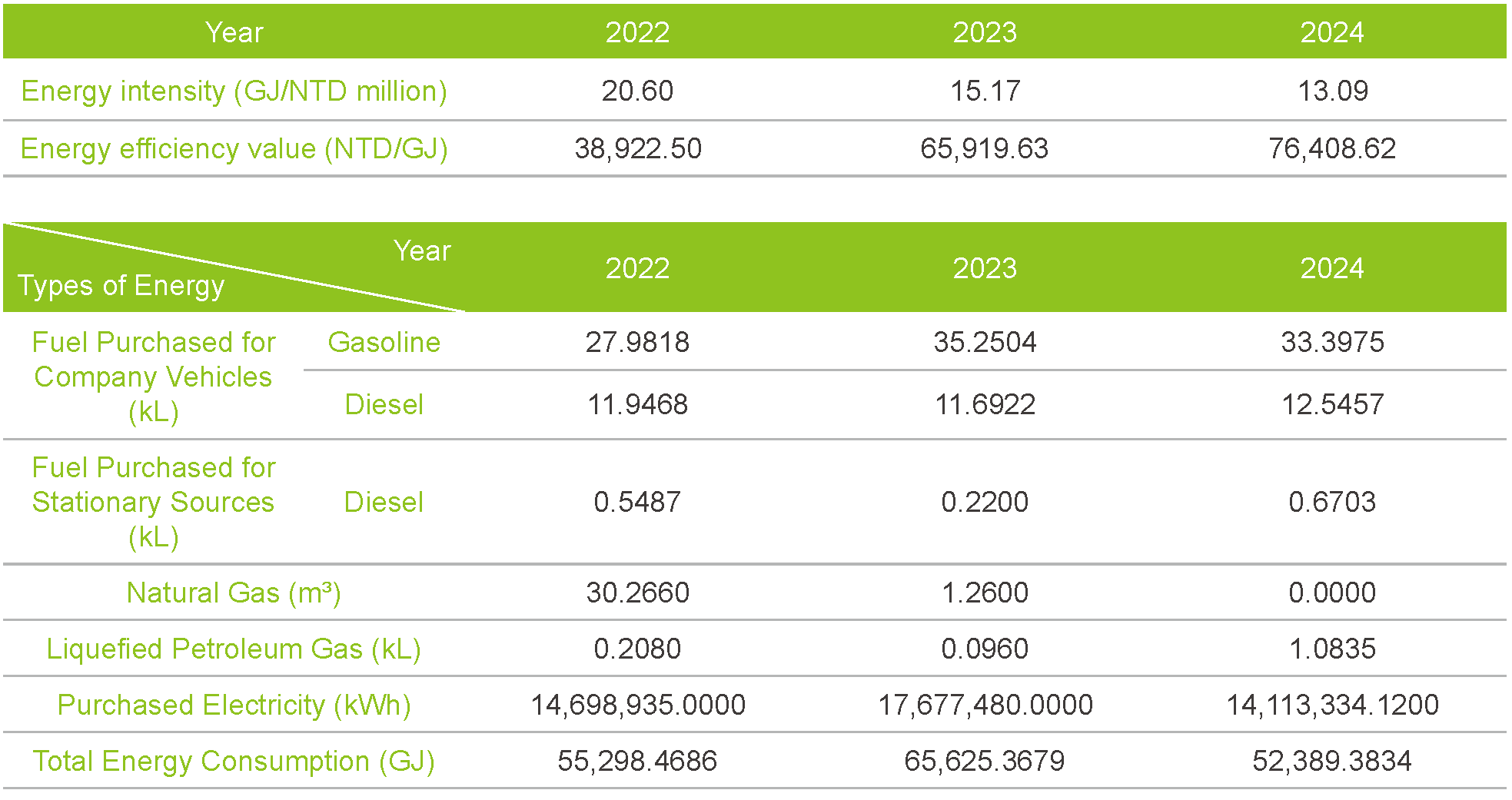

The Company introduces new energy conservation measures on a yearly basis, such as purchasing energy-efficient models, replacing outdated machinery, and optimizing production schedules. Kaori draws on the wisdom of many to achieve energy and carbon reduction goals. In the future, more attention will be directed toward improving production procedures and reducing energy consumption and promoting Kaori as a green, sustainable business. Energy intensity was lowered by 13.71% in 2024 compared to 2023.

Energy Efficiency and Energy Intensity Performance Over the Past Three Years

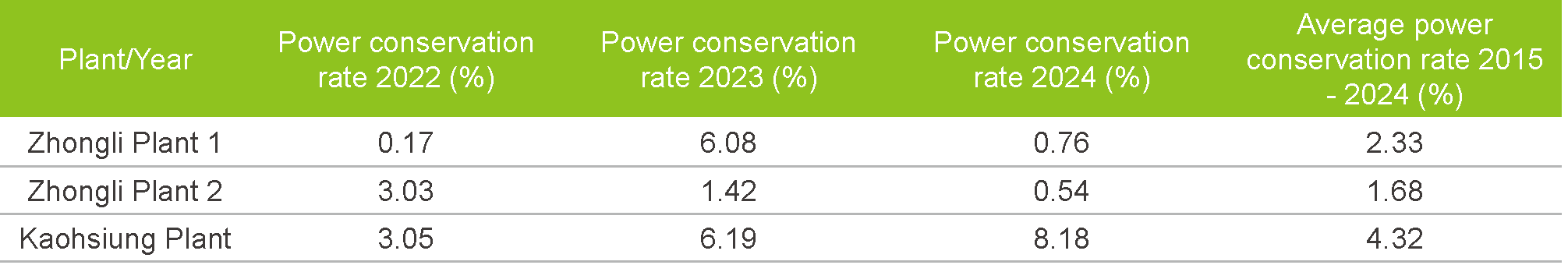

All plant sites comply with the laws of the Bureau of Energy, Ministry of Economic Affairs. As a major energy user that Taiwan Power Company has signed a contract with to supply at least 800 kW of power, the Company reports annual energy performance and improvement plans in accordance with Article 9 of the Energy Administration Act. The Company has set goals to achieve an "annual power conservation rate" or "average annual power conservation rate" of more than 1%. The Zhongli Plant 2 and Kaohsiung Benzhou Plant have appointed dedicated energy management officers to enforce energy conservation plans and achieve an average annual power conservation rate of more than 1%.

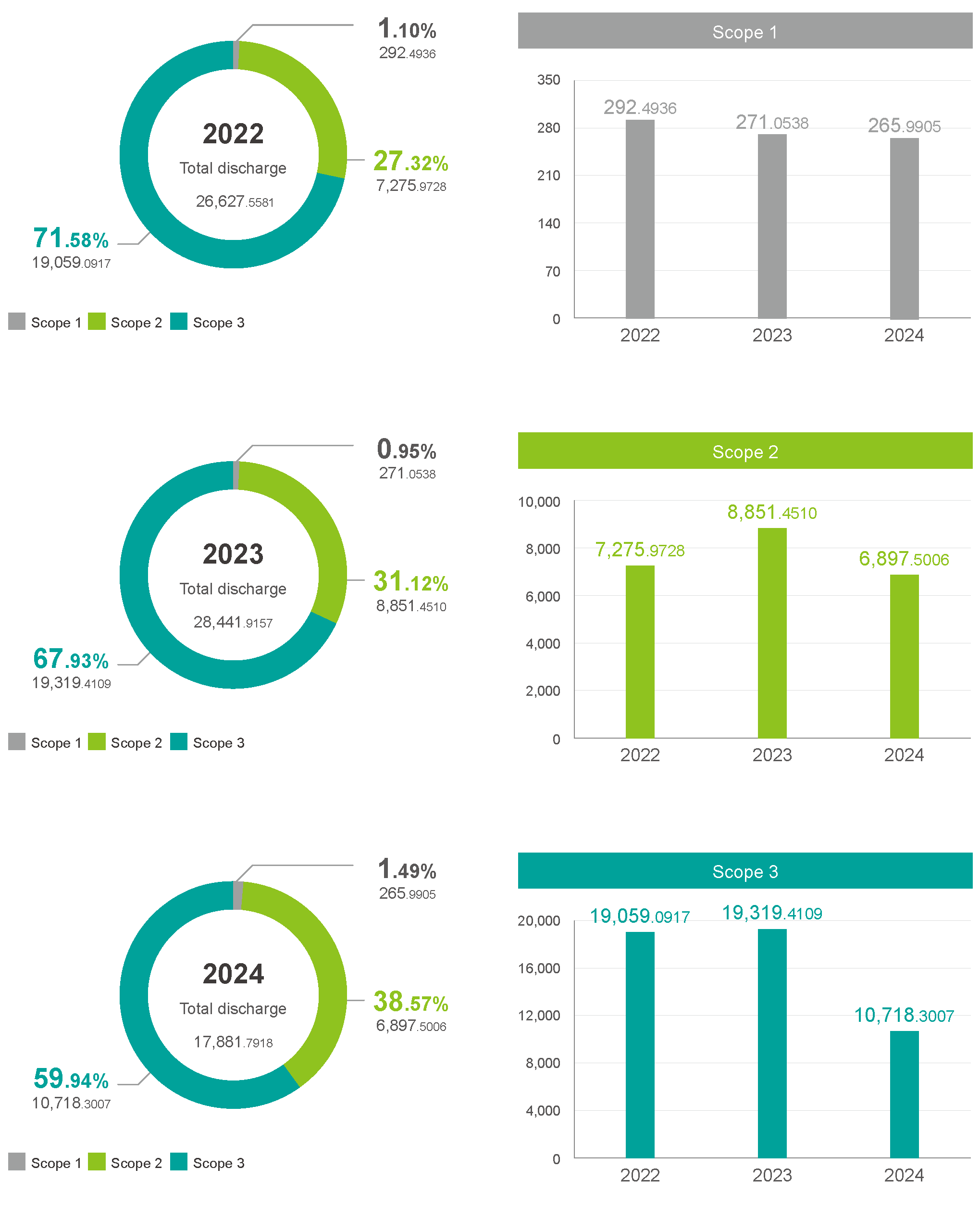

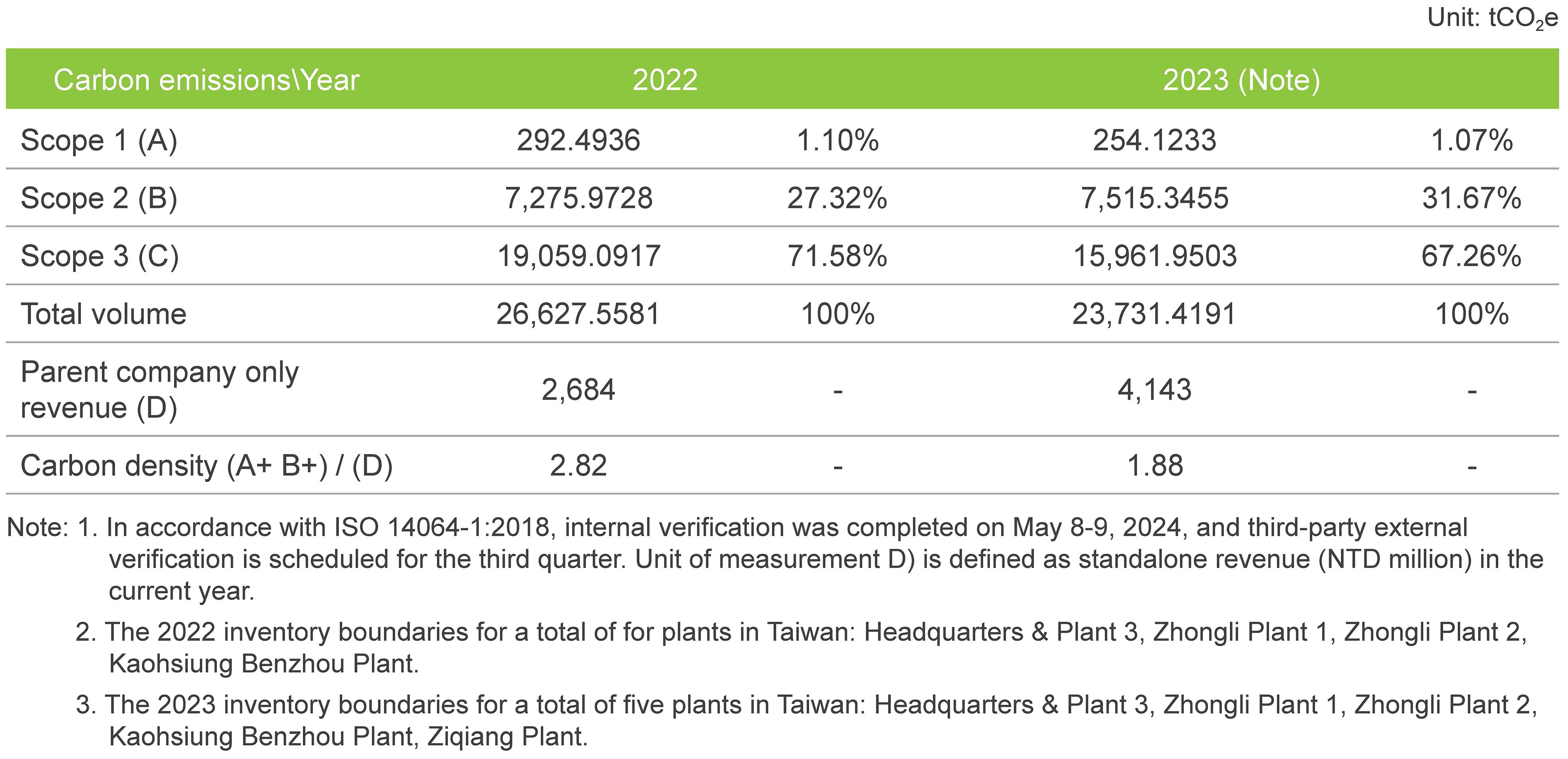

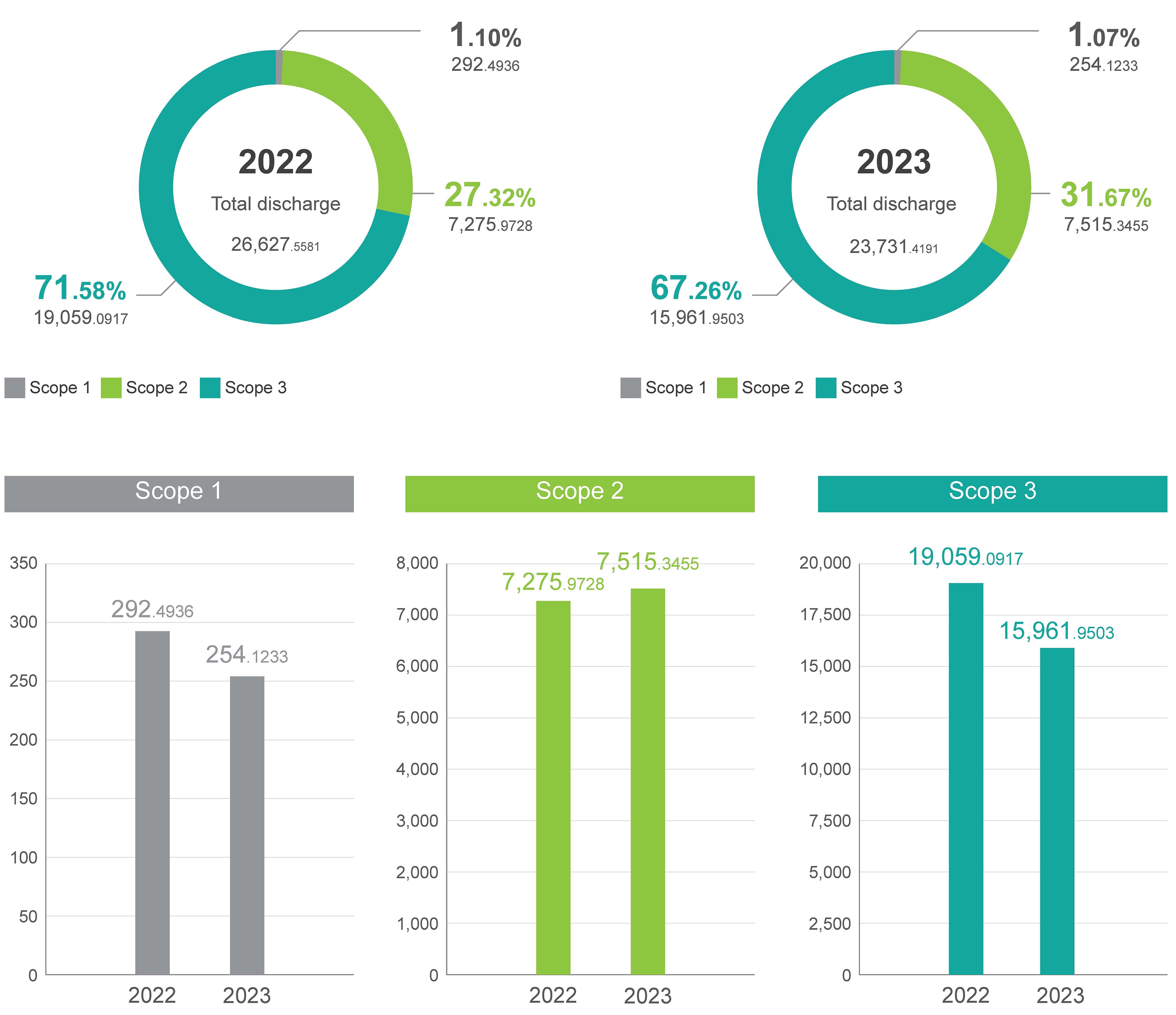

Since 2021, Kaori has been implementing the ISO 14064-1:2018 greenhouse gas inventory standard. For the third consecutive year, Kaori has passed third-party inspection and verification with a 100% achievement rate. Furthermore, the subsidiary in Ningbo, China, completed its inventory and verification process in 2024, following the same procedures as the parent company

The inventory is conducted in accordance with the ISO 14064-1:2018 Greenhouse Gas Inventory Standard. The boundary scope covers all factories and subsidiaries in Taiwan, with a total of six sites. The internal verification was completed from April 23 to April 25, 2025, and the external verification will be completed in the third quarter of the same year. Driven by the internal Carbon Management Committee, preliminary calculations based on collected data show that total Scope 1 and Scope 2 emissions in 2024 amounted to 7,163.4911 tCO 2e, representing a 15.14% reduction in carbon intensity compared to 2023.

Kaori did not emit any nitrogen oxide (NOx), sulfur oxide (SOx), or other gases of significant impact.

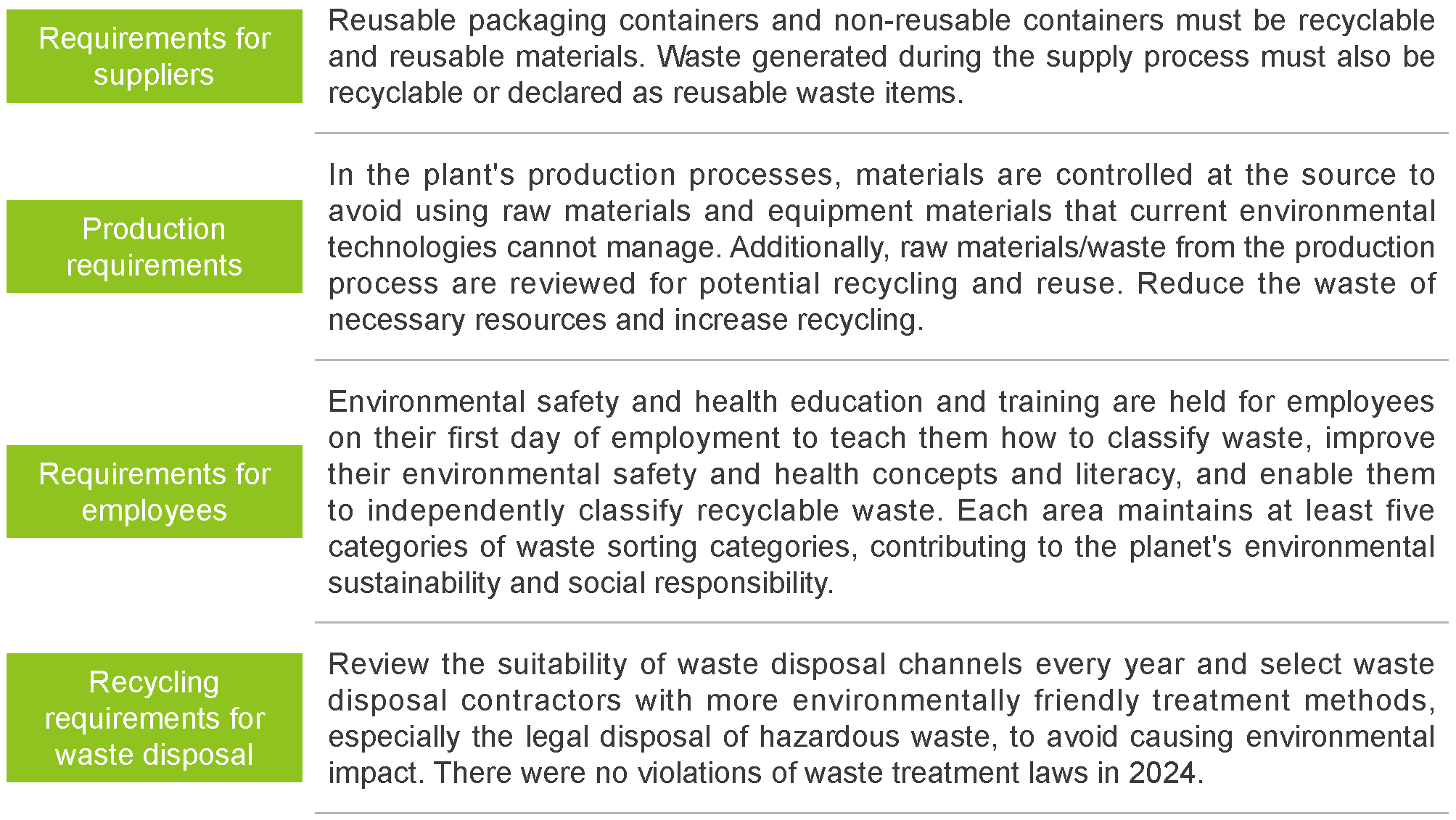

Kaori observes the ISO 14001 standard and has created a dedicated unit to track the sources and volumes of waste. Adhering to the principles of maximizing resource use and minimizing waste generation, the Company promotes "Waste Management Measures." All departments are committed to minimizing waste volumes from production activities, increasing the life cycles of raw materials used, and promoting the circulation and reuse of resources and waste for total waste reduction. Kaori engages qualified service providers to dispose of waste and uses appropriate forms to audit waste handlers, thereby ensuring the appropriateness of waste treatment and that the waste generated does not pose a significant impact on the nearby environment.

Kaori reduces the volume of waste by recycling waste iron, carton boxes, and waste glass and reusing waste pallets. Waste pallets are handed over to qualified service providers for reuse, thereby minimizing environmental impact. Upholding the principle of responsibility, Kaori duly reports how waste generated from plant sites is handled and retains complete documents to ensure that waste is properly treated.

Climate change has emerged to become one of the most critical issues in the 21st century. Extreme weather, floods, and droughts in recent years have prompted government agencies, businesses, and private organizations to undertake more active mitigations of the risks. Meanwhile, Kaori contributes its part to environmental protection and social values by enforcing energy management throughout its operations and by investing into the research and development of new materials and production procedures.