Suppliers' implementation of social responsibilities

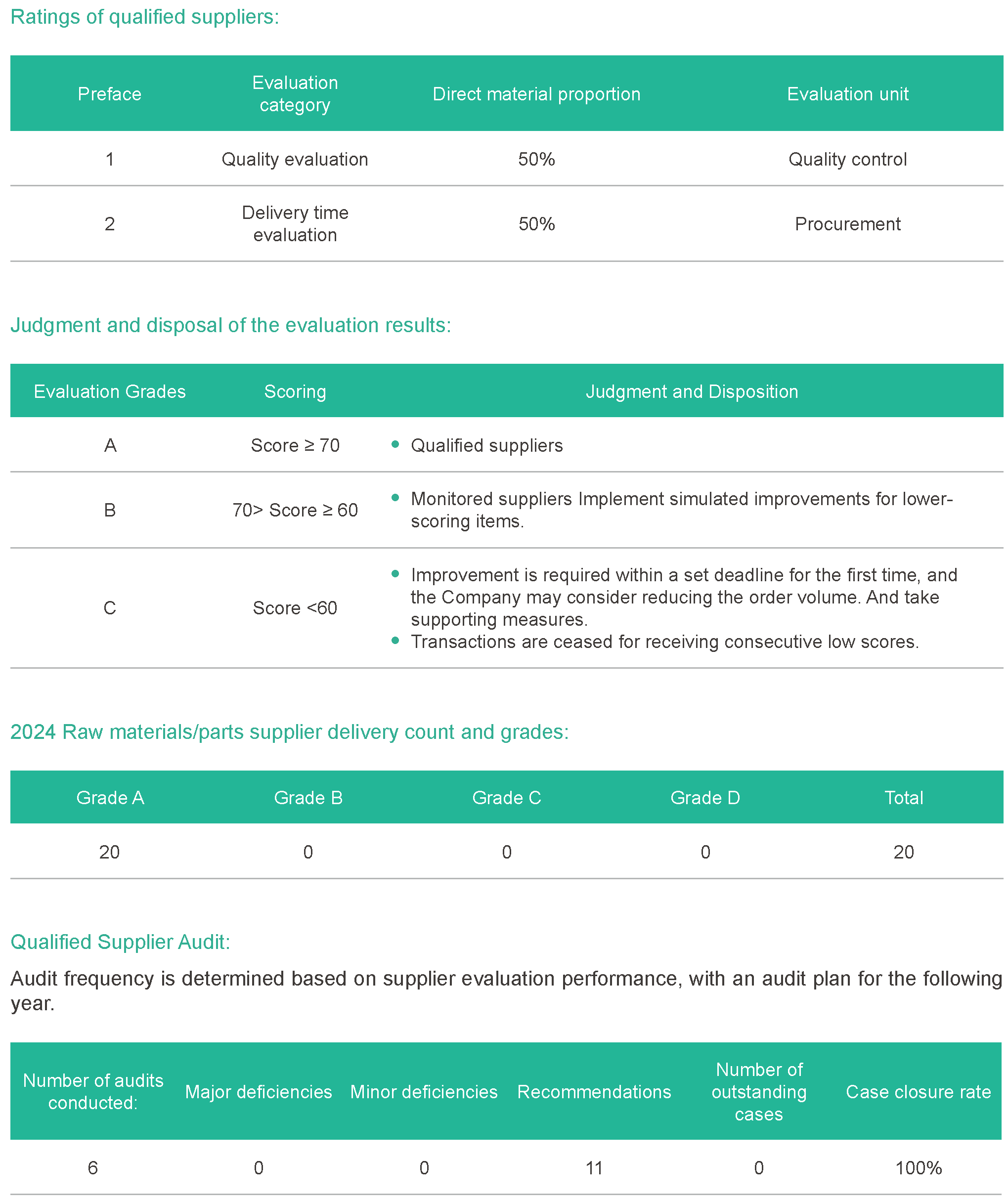

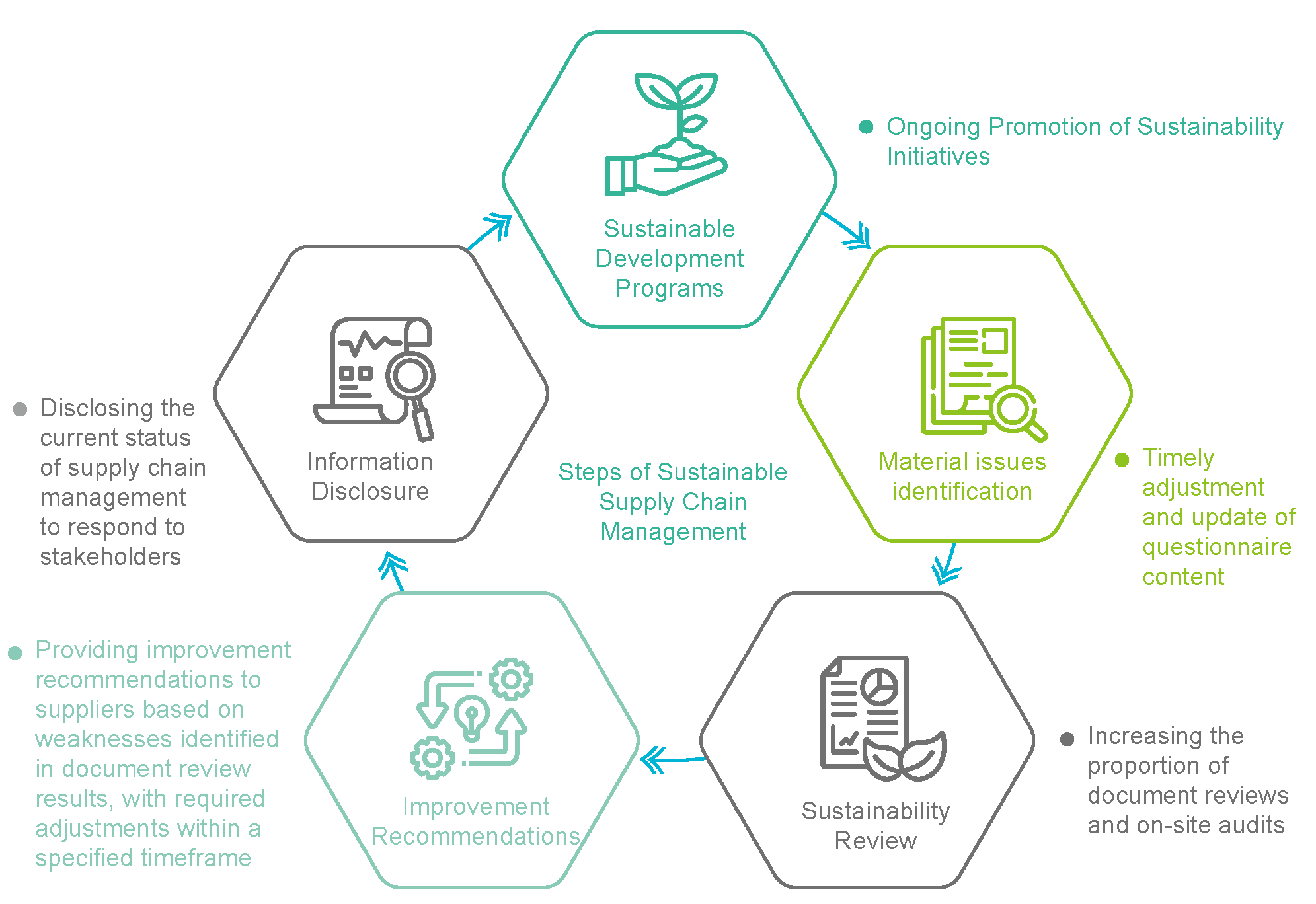

The Company has established the Supplier CSR Code of Conduct in accordance with the Responsible Business Alliance (RBA) as the basic value for managing the supply chain. This Code covers labor, health and safety, environmental standards, business ethics, and management systems to ensure that suppliers work in a safe environment, employees are treated with respect and dignity, and business operations are environmentally friendly and ethical. The Company requires suppliers to avoid risks related to the environment, human rights/labor, corporate ethics, and labor standards, as well as prevent production stoppages caused by strikes in advance, and establish a relationship of co-existence and co-prosperity with suppliers.

Responsible Mineral Procurement

Kaori complies with the Responsible Business Alliance (RBA) and is committed to not purchasing or using materials from conflict-affected and high-risk areas. The Company communicates its conflict minerals policy to suppliers, requiring their commitment and compliance. Suppliers are also required to trace the sources of tantalum, tungsten, tin, gold, and cobalt used in their products. At the same time, suppliers are required to communicate this policy to their upstream suppliers to fulfill corporate social responsibility. Kaori publicly discloses its conflict-free minerals policy on its website and integrates it into supplier management. Suppliers are required to sign a Non-use Conflict Minerals Guarantee, ensuring that all materials, products, or components delivered to Kaori do not directly or indirectly contain conflict metals.